Valve Maintenance – A never ending task aboard ship

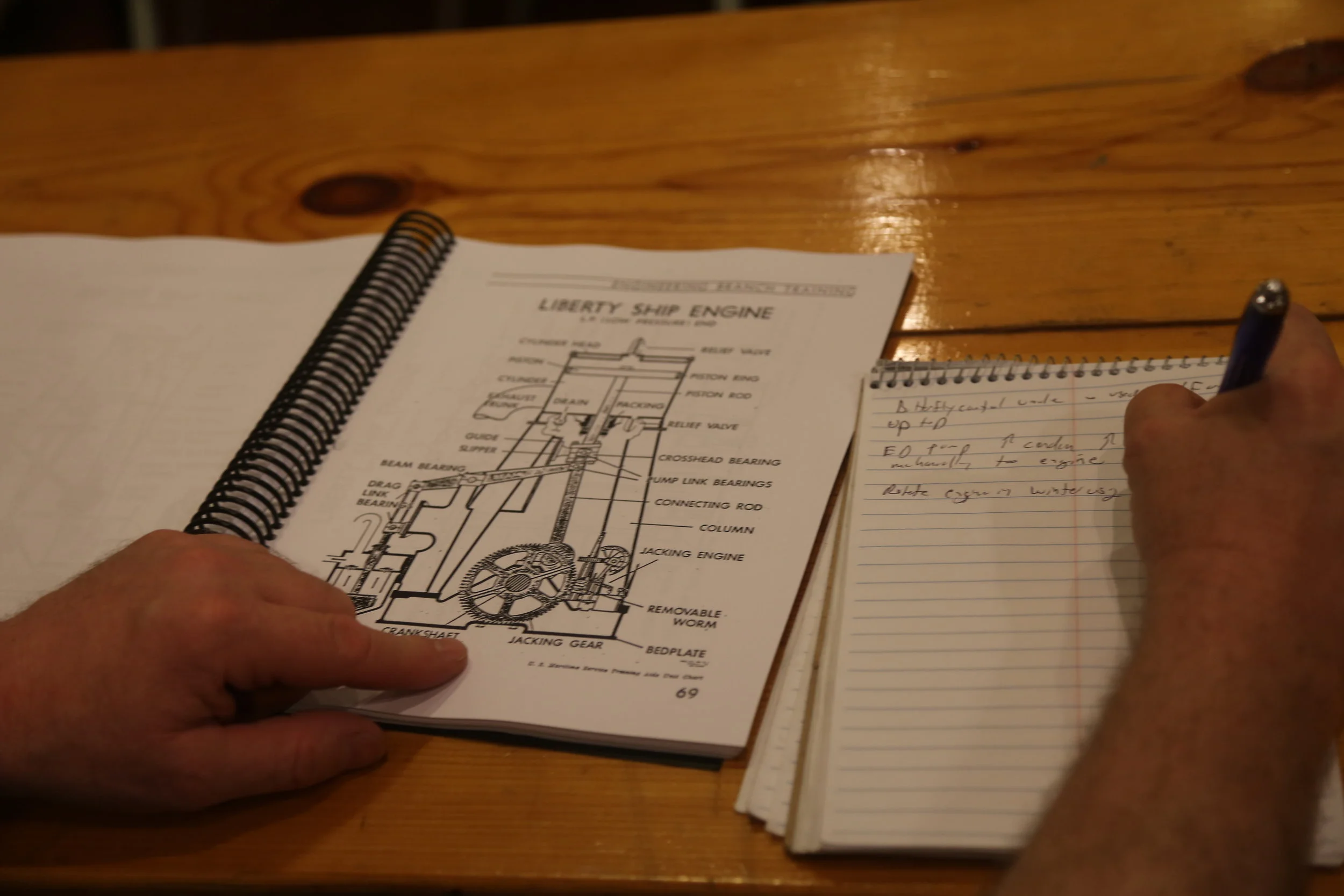

Hundreds of valves are present in the piping systems found on Liberty ships to control and direct the flow of fluids and gases, including steam, that are part of the ship’s engineering systems. The proper operation of these valves is essential for the safety and efficient operation of the engineering plant. A system of regular inspection, maintenance, and repair is necessary to ensure the valves operate as designed and this is included as a normal part of the ship’s work schedule. In other words, we'll be having some Coast Guard Inspections soon... :)

Most of the engineering maintenance on JOHN W. BROWN is scheduled during the winter months when the ship is not steaming to conduct Living History Cruise and port visits. This year’s valve maintenance effort is focused on the boiler-mounted valves. These are valves located on the boilers or are the first valve from the boiler on a system connected to it and is subject to full boiler operating pressure (~200 psi for a Liberty ship). Coast Guard requirements call for these valves to be removed from the boiler at periodic intervals for inspection and that milestone occurs this winter.

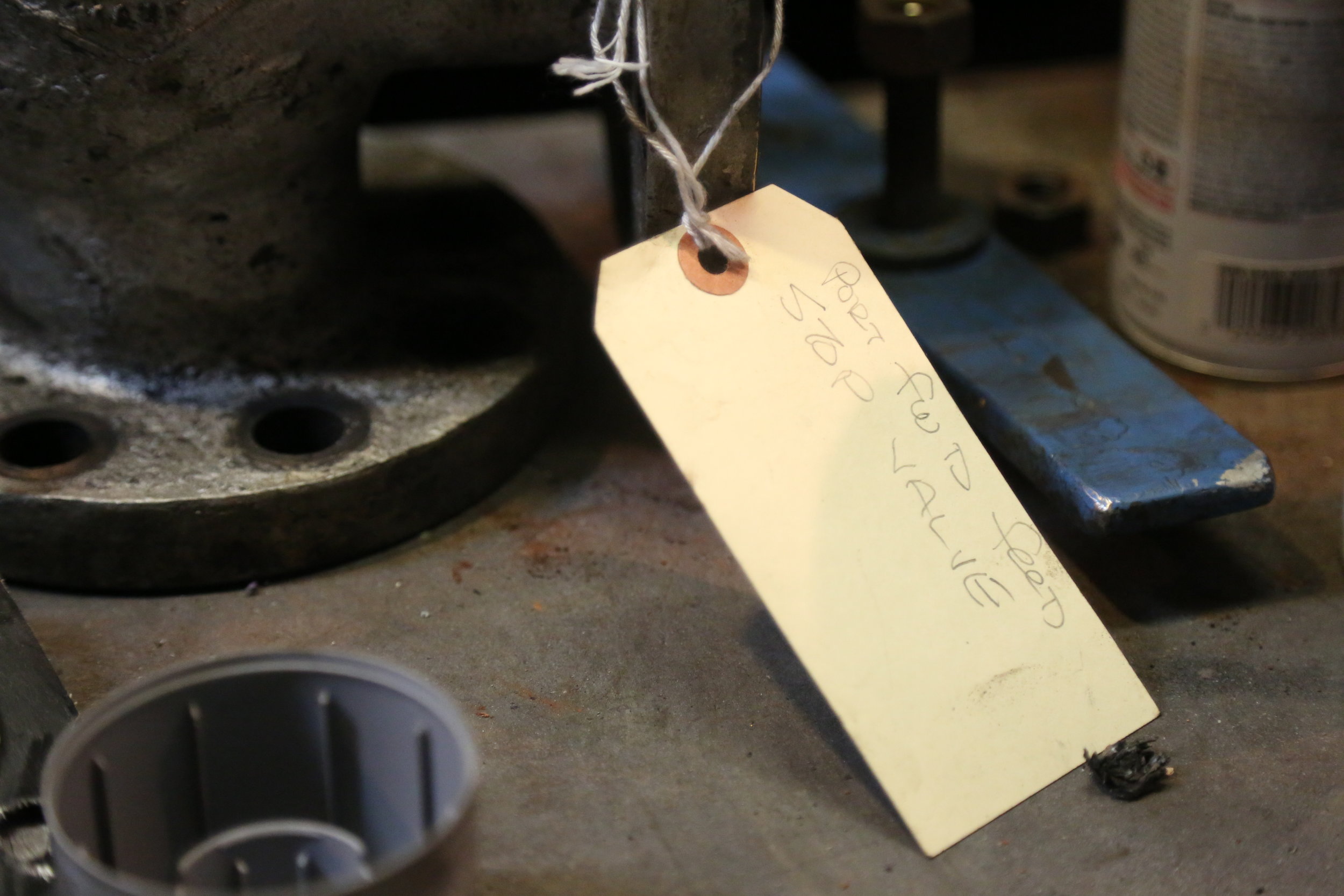

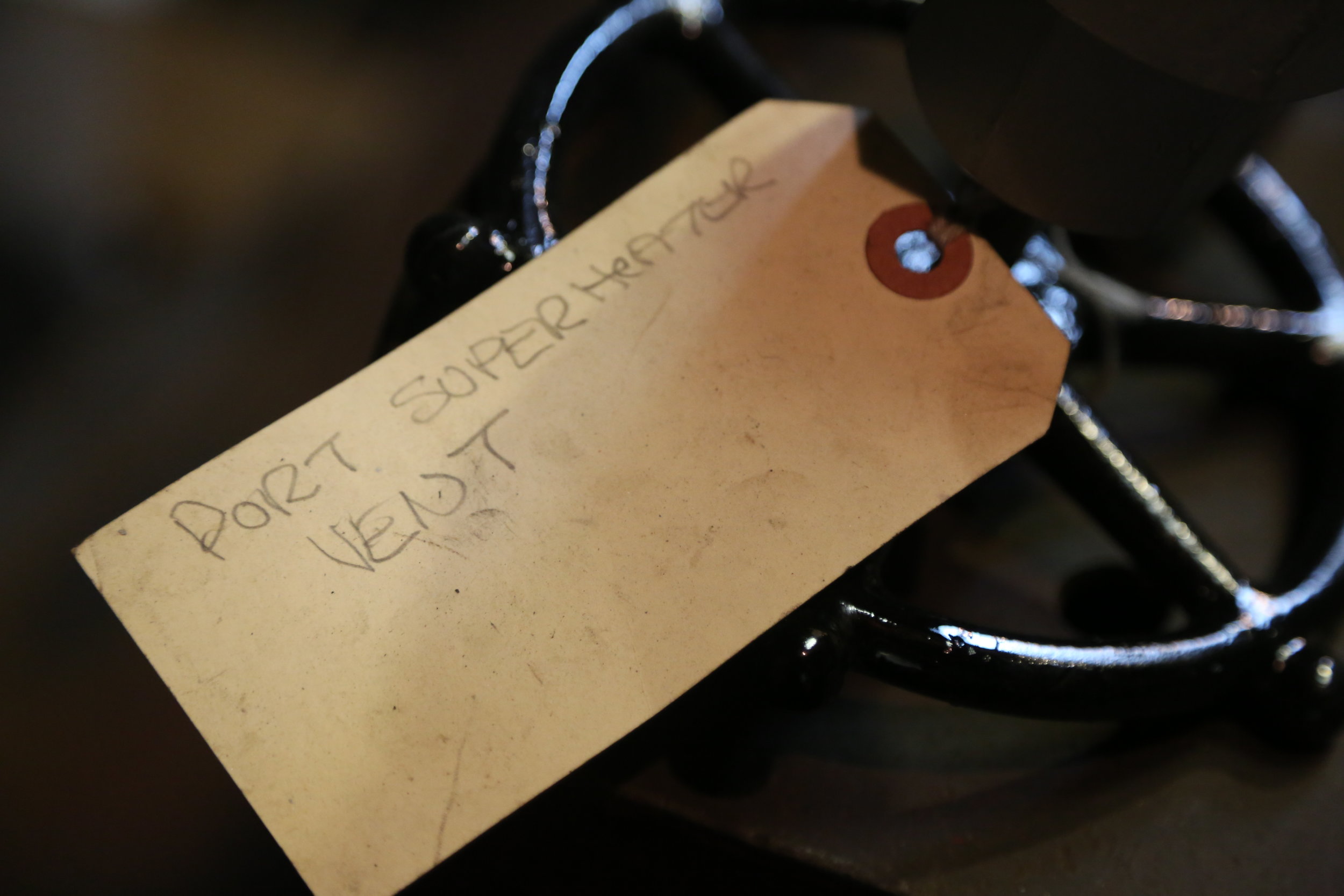

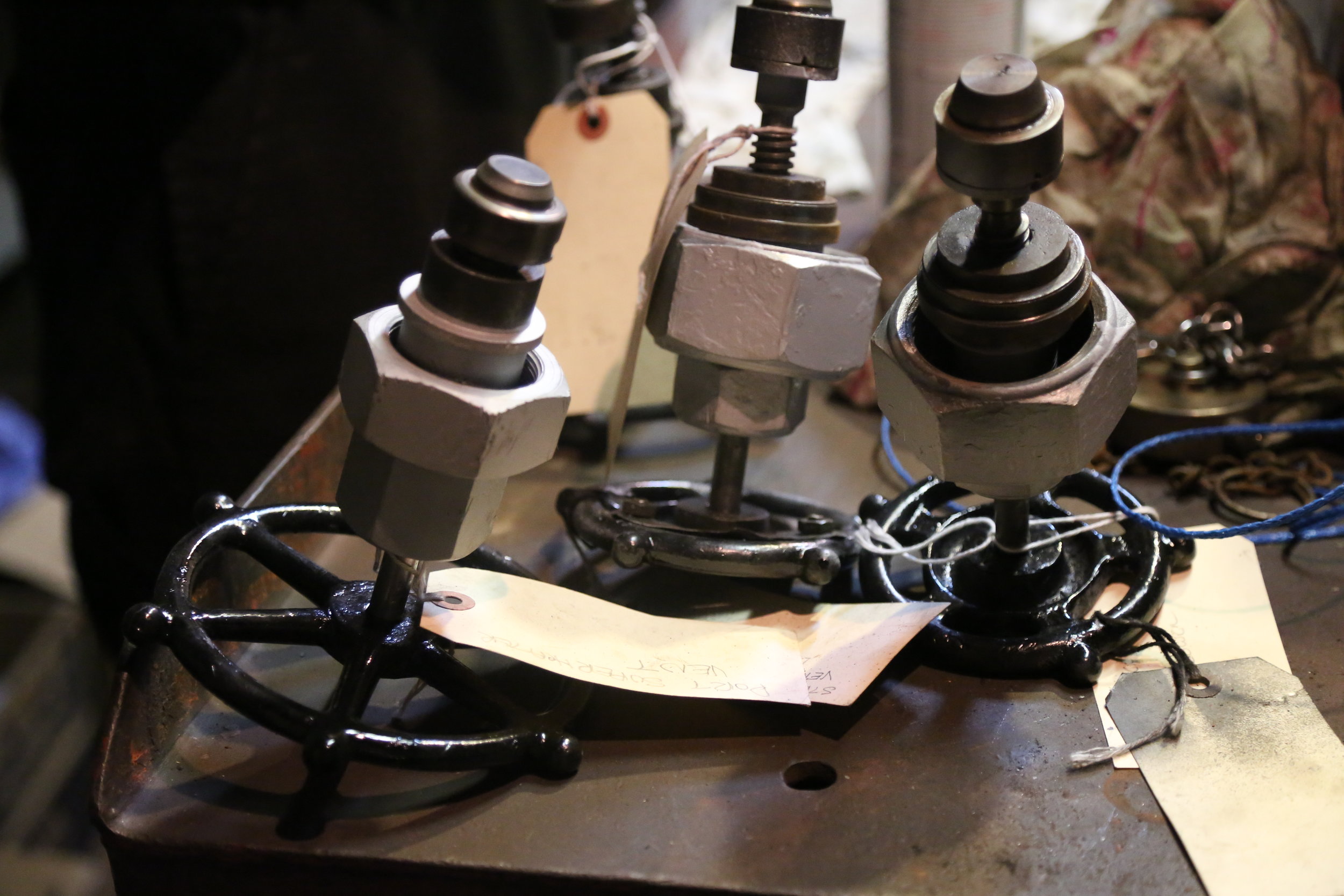

The valves are completely overhauled for the inspection. This includes disassembly of the valve, cleaning the individual components, lapping the mating surfaces of the valve disc and seat to insure the valve doesn’t leak when shut, replacing the packing around the valve stem to prevent leaking around this part of the valve that is turned during operation, and replacing the gaskets where the valve is connected to the flange of adjacent piping. If a part is found to be defective, it is repaired or replaced. In addition, all the hardware used to secure the valve to the adjacent pieces of the piping system is being replaced with studs and bolts that are rated for the temperatures and pressures present in the system.

Volunteers have removed the first 16 valves and have begun overhauling them to prepare for inspection. The valves include a range of sizes and designs. As work is completed on the initial valves, additional ones subject to the inspection will be removed and overhauled in the coming weeks. When the inspection is complete, the valves will be reinstalled on the boiler until the next inspection milestone.

This is just more proof that the work is ongoing and will never be done on the JOHN W BROWN. We are always looking for individuals that are good with their hands and willing to help out. And no experience is needed. Project Liberty Ship and our wonderful gray lady, is always doing on the job training in many different ways. On this specific day, there were men painting, grinding, disassembling, reassembling, making new gaskets, working with wire brushes and this was just in one section of the engine room. Thanks for reading and thanks for the interest in the SS JOHN W BROWN.

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.